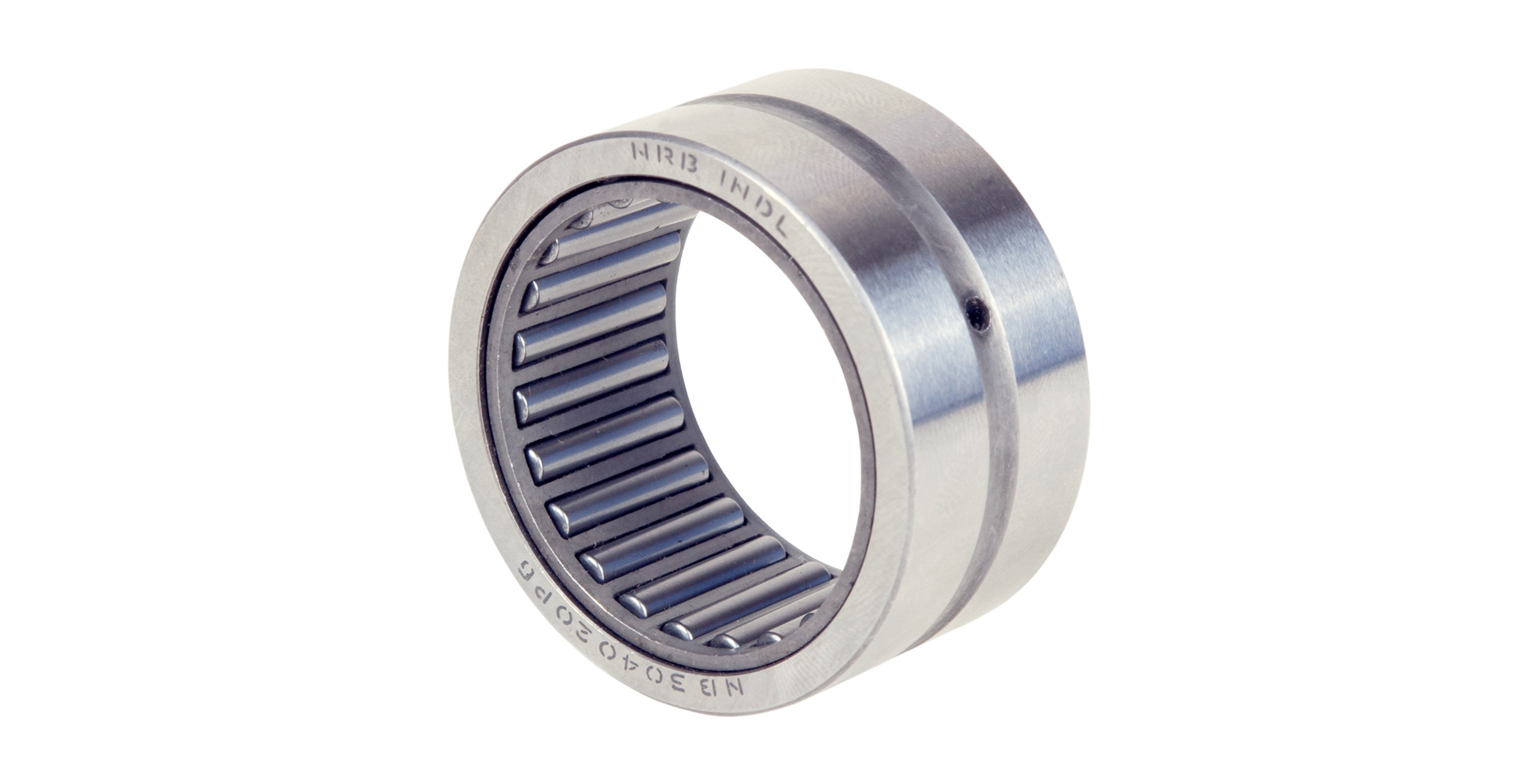

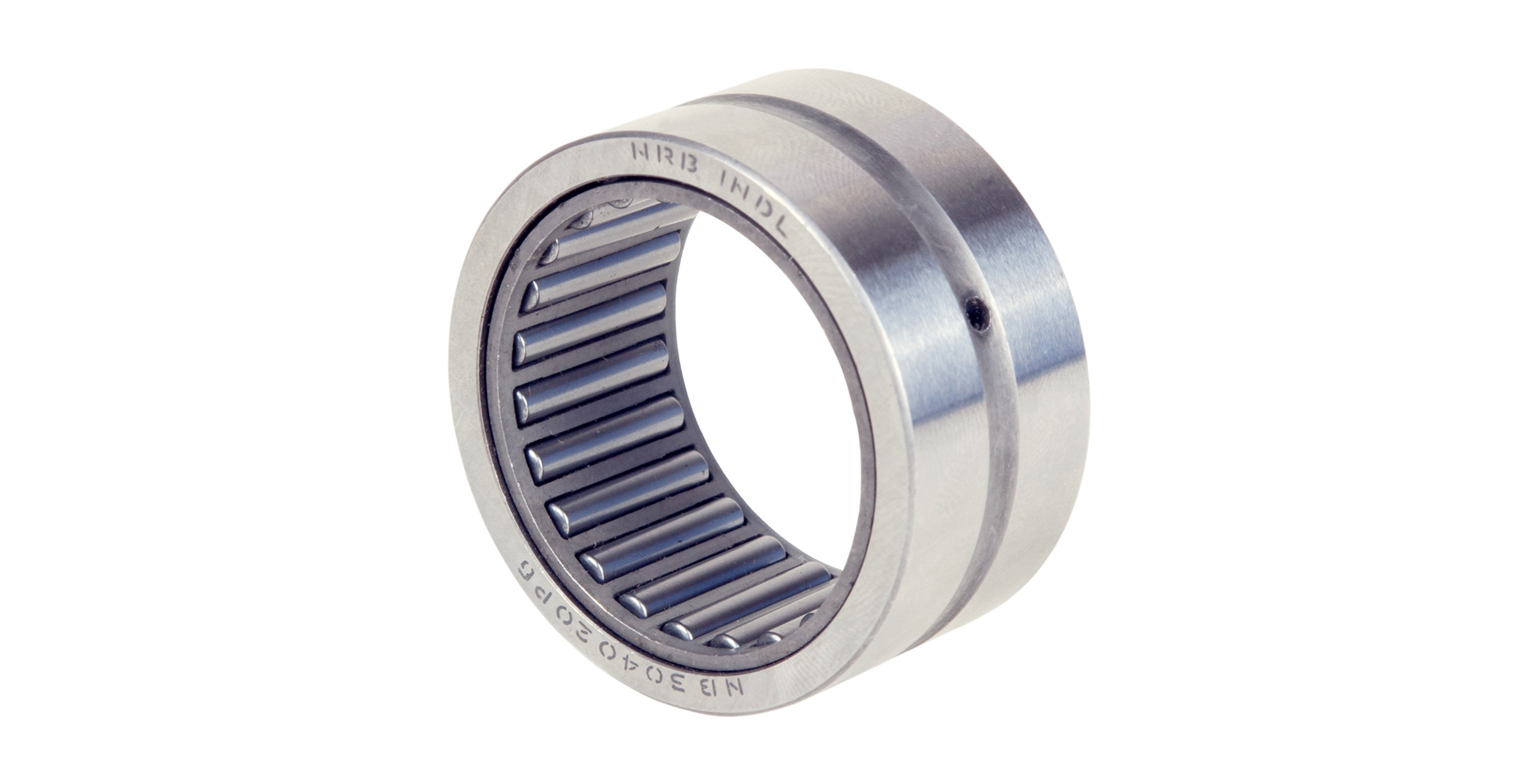

Caged NRB

NIBL’s caged needle bearings, which have a high load carrying capacity, consist of outer ring made from through- hardened bearing steel. The cage guides the needles and retains them in the outer ring. The bearings may be used without an inner ring if the shaft journal serving as a raceway is of sufficient hardness and has the correct surface finish. To ensure that the full load capacity of these bearings is achieved, a hardness of 58-64 HRC is required.

The basic construction of needle roller bearings is;

o With integral end flanges on both sides, channel shaped outer rings

o With inserted end washer to provide axial retention of needles roller and cage assemblies

Needle roller bearing with integral flanges

The needle roller bearing has one piece, channel shaped outer ring of bearing quality steel heat treated to yield maximum load rating.

The integral end flanges provide axial location for the needle rollers. The bores of the end flanges serve as piloting surfaces for cages.

A steel cage provides inward retention for the needle rollers and the design assures roller stability and minimizes friction between the cage and the needle rollers. The cage has maximum strength consistent with the inherent high load ratings of needle roller bearings. The outer ring has a lubricating grove and a lubricating hole for more convenient lubrication of the bearing. However smaller sizes don’t have lubrication hole.

Series :

NB, NBI

NA-49

NA-69

Min ID :- 10 mm

Max ID :- 120 mm

Min OD :- 19 mm

Max OD :- 180 mm

Cage Variants :-

1. Welded Steel Cage

2. Machined Steel Cage

3. Polyamide Cage

etc.