Industry Challenges: A loose fit for a bearing will lead to relative movement between mating components, resulting in fretting, smearing, scoring, wear, excessive heat, and/or fracture. A extra-tight fit will reduce the bearing’s internal clearance, which will increase the operating temperature of the bearing in operation. Increase in mounting forces required, but can lead to fracture of bearing’s.

Introduction : When a bearing is mounted without proper care — without utilising the correct knowledge and tools — the bearing’s service life will be cut short. As per the industry estimates, estimated 16 percent of all premature bearing failures are due to poor fitting and the lack of knowledge) of the right fitting tools. The best practices for mounting a bearing can avoid future problems and extend bearing performance and service life. This will be visible, in the efficiency and productivity of an operation with an increase in machinery uptime.

Methods : The primary methods for proper mounting of a bearing are classified as “cold” or “hot,” as per the shaft diameter or bearing inner diameter. Cold mounting, or mechanical mounting, generally is recommended for small- and medium-sized bearings.

Hot mounting will be for larger bearings; and hydraulic techniques should be used when mounting especially large bearings. Tools have been developed to take care of each particular bearing needs.

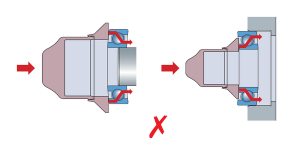

In cold mounting, the wrong practice of using a hammer and pipe for the job is not recommended as will damage the raceways. This can also allow contamination to enter the bearing or, if not done properly, a pipe can slip and impact the rolling element of the bearing. The best practice recommended is to use fitting tools to eliminate the possibility of damage from force, not acting in line with the shaft and bearing position. Fitting tools ensure the proper force is applied to both bearing rings and isolates the rolling elements from impact force, thus assuring a more reliable installation and limiting the risk of damage.

Hot mounting, where the bearing is pre-heated, provides a fool proof solution to allow for a bearing’s inner ring expansion and subsequently easier installation, while maintaining specified interference fit or tolerances after the job is completed. It also saves time , free from any risk of lower flash point of the used oil being used , free from dirt entering the rolling elements and acting as abrasives.

For example, conventional hot oil baths raise the probability of contamination (and premature bearing failure) and flashing. Other techniques (such as exposure to an open flame) fall short, too, and can be potentially dangerous. Induction heating is highly recommended, which involves heating bearings to be mounted prior to installation to allow for a high degree of control, efficiency and safety.