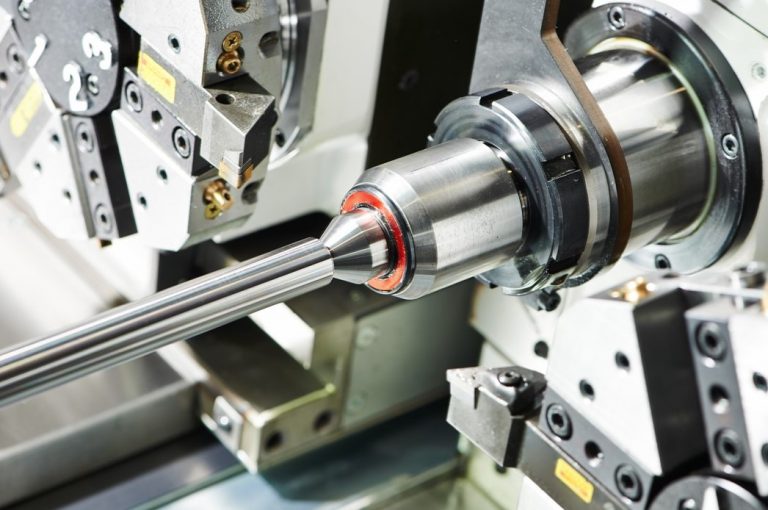

Planning for proper fit between the bearing and the shaft or housing is as important as bearing design and cleanliness. Improper bearing fits or incorrect installation can damage the bearing assembly.

The ideal mounting for a bearing is line to line on both shaft and housing. Such a fit has no interference or looseness. For random fitting the fit tolerances may need to be increased to meet the lot variances. For selective fitting the bearing inner and outer diameter should be accurately measured, then the shaft and housing machined to suit.

Interference fits should be used with care as they can distort the raceway and reduce radial internal clearance. In preloaded pairs, reducing the internal radial clearance increases the preload. If excessive, the results can be significantly reduced speed capability and higher operating temperatures which will ultimately reduce life.

Some applications require interference fits such as:

Radial internal clearance is reduced by approximately 80% of the interference fit.

Interference fits are usually applied to the rotating ring.

Loose fits may be suggested when:

Fits are often overlooked and is arguably the most common bearing handling mistake.

The table below is simply a guideline as there are many influencing factors to be considered such as.

Therefore the appropriate fit may fall somewhere in between.

| ROTATING RING | |||

|---|---|---|---|

| APPLICATION | DESIRED FIT TYPE | FIT(inches) | |

| Low speed, or spring preload. | Loose | .0001L to .0005L | |

| Medium speed | Line to Line | .0002L to .0002T | |

| High speed | Light press | .0000 to .0004T | |

| High speed, high load | Tight press | .0002T to .0006T | |

L = Loose fit, T = Tight fit, d = Bearing I.D., D = Bearing O.D.

Selecting the right bearing for a specific application requires a review of performance requirements and material operating limitations. Certain design considerations must be met in the device and bearing to address such factors as load, speed, temperature, environment, method of lubrication and fit. Often times sacrifices must be made in one area to satisfy another to achieve optimal life.

Many factors come into play when selecting a bearing or creating a new design in which a ball bearing will be employed. Most important are speed, load and temperature.

| Load | Speed | Temperature | Environment | Shaft / Housing |

|---|---|---|---|---|

| Direction | Constant | Average | Vacuum | Fits |

| – Radial | Variable | Max. | Gas or Air | Geometry |

| – Axial | Hi or Low | Operating | Contaminants | Tolerances |

| – Shock | dN> | Ambient | Mounting | |

| – Combined | 250,000? * |

*d=bore in mm, N=RPM